When it comes to growing cannabis, having an HVAC system is one of the most important components to the success of your growth. HVAC systems have the ability to regulate temperature, humidity, air quality, airflow, provide ventilation and more.

It’s critical to have multiple disciplines work together to maintain optimal conditions, each performing at its peak to protect crops and produce the highest yield and quality product. Here at Continuum, our engineering and maintenance experts provide essential expertise in energy savings, temperature, humidity, air quality control and disinfection.

With the full weight of our proven team and experience in HVAC services, we will work with you to put in place processes and procedures that will create and maintain stable and precise conditions. We are onsite, with back-up at all times, leaving nothing to chance. The result: the highest yields, and quality and consistency in every individual plant.

Cannabis HVAC Solutions

A deficiency in one or more cultivation systems can impact facility performance, reducing yields and market competitiveness. Since December 2020, nearly 1.6 million plants did not meet required standards and were destroyed, according to Marijuana Regulatory Agency data.

Our engineering and maintenance expertise helps control and eliminate environmental risk factors in your operation that could compromise your harvest. Continuum Services is here to give you peace of mind.

Why HVAC Maintenance Expertise is Critical

Proper HVAC system maintenance is a complex undertaking, extending to refrigeration circuits, lubrication, water treatment, air quality and other specialty tasks. Our experienced maintenance team provides the expertise essential for a grow facility to function at peak performance.

Without consistent, onsite maintenance, your grow room climate system will begin to underperform in ways that aren’t easy to detect:

- Dirty filters will limit airflow across the cooling coils, forcing them to run more often to achieve sufficient cooling, or not achieve sufficient cooling at all.

- Dirty strainers in chilled water systems will force pumps to work harder and can result in diminished chiller capacity due to flow rate disruptions.

- Uncleaned condenser coils will limit heat exchange in the refrigerant circuit, resulting in less cooling output in exterior units.

Diminished capacities caused by improper maintenance initially impact energy use. The systems begin using more energy than needed to do the job, affecting your bottom-line operating costs.

As maintenance issues progress, systems may begin to fail to maintain climate parameters consistently, which can lead to inconsistency in yields. It can also create biosecurity risks as fluctuations in humidity and temperature can leave plants particularly vulnerable to fungus and other pests.

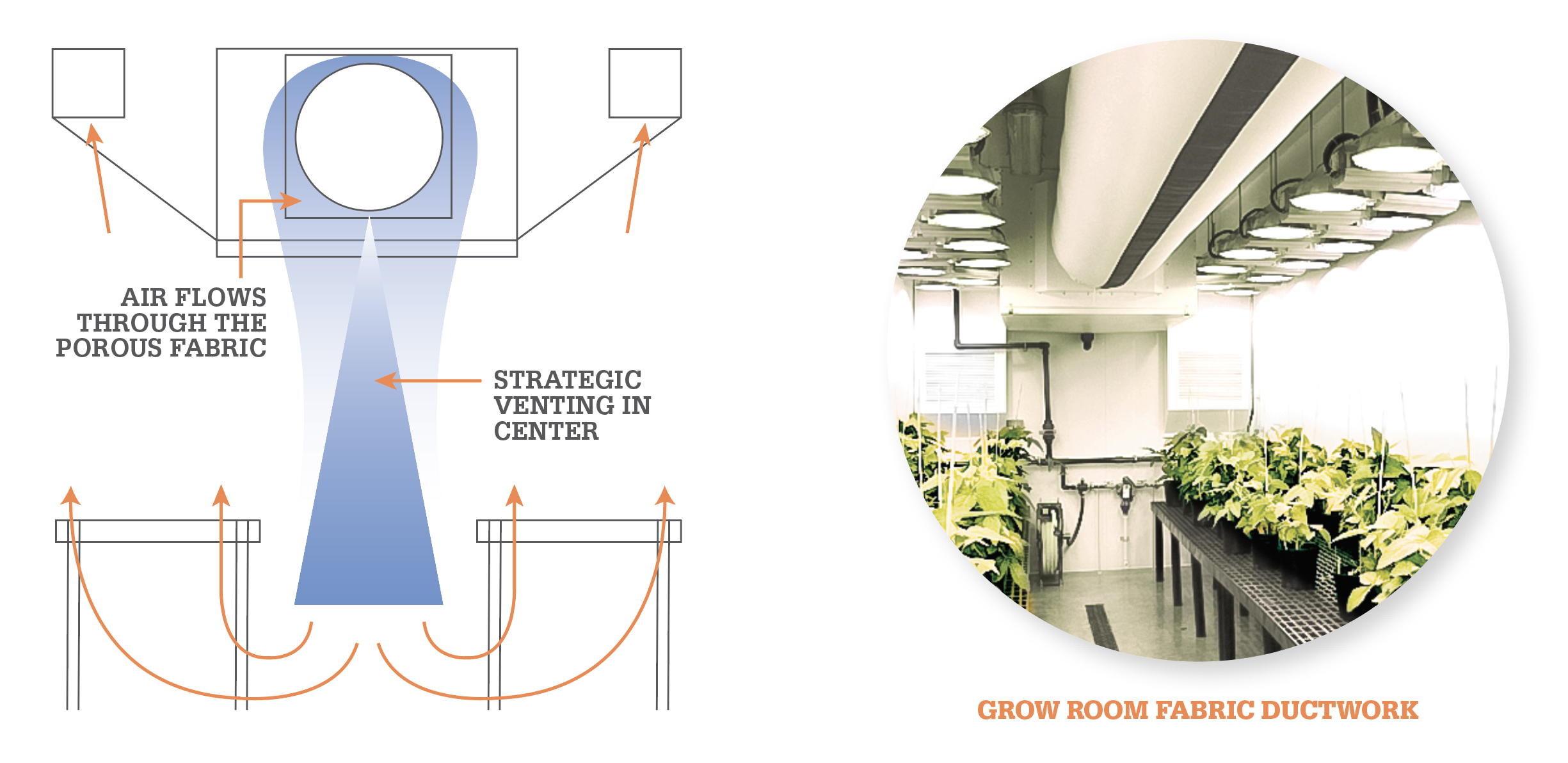

The Important of Air Movement

One of the most critical elements to success is proper air movement across plants:

- Air movement is intimately tied to plant transpiration rates.

- Too little movement results in micro-climates.

- Too much focuses growth on the stem rather than the flower.

The Continuum Services Advantage

Dedicated engineering and maintenance capability with 24/7 service means ZERO downtime. We provide an onsite team backed by the entire Continuum Services family – there will always be coverage in cases of illness, vacation or COVID-19. We will maintain your equipment so your team can focus on your core business.

Our dedicated team provides immediate, ongoing service:

• Full-time, onsite building engineering & maintenance services and general building maintenance & repair services

• Mobile/temporary building engineering & general maintenance services

Our responsibilities and capabilities include:

• HVAC equipment for preventative maintenance and plumbing repairs

• Computerized maintenance management software (CMMS) to implement, manage and schedule services and maintenance

• Energy and utility maintenance, management and reporting, including EPA Energy Star Portfolio Manager, benchmarking, rebates, incentives, etc.

• Account and facility maintenance management

• Facilities capital, repair and maintenance planning and budgeting

• Streamlined and timely facility operations and maintenance services with single-source service provider

• Scheduled facility audits, inspection and reporting

• Quarterly business reviews (QBR), service level agreements (SLA) and facility scorecard with performance metrics

One of the key factors in having a successful harvest is controlling your environment. When inefficient environmental solutions cause mold and fungus, crops can be destroyed. Our engineering and maintenance experts will create and maintain stable and precise conditions to help ensure the best outcome for your grow facility.

Call (248) 286-5200 to discuss how Continuum Services can help grow your business.